With 35 years of experience, we are a trusted partner in the defense and aerospace industry, continuing to shape the world of tomorrow. We have received R&D awards and support from TÜBİTAK and the European Union. With our determination, research capabilities, and technical expertise, we remain the first and only manufacturer of certain specialized products in Türkiye. We carry out all processes—R&D, design, prototype development, and mass production—under one roof, operating under three distinct brands. Our products, which hold significant importance in the defense sector, are manufactured in compliance with NATO and Turkish Armed Forces (TSK) standards, and we take great pride in contributing to special projects.

Preconditioned air equipments which are being produced with 25 years of experience are used in ground support systems at airports. • Cost-efficient • Practical • Long life of service maintanance • Insulated hoses • All in one: heating-cooling-ground power unit

Our ground support equipment is developed to support all aircraft operations on the apron, offering reliability, durability, and high efficiency.

Designed to withstand harsh environmental conditions, shelter-type air conditioners reliably meet the climate control needs of both mobile and fixed shelters. With their compact design, high cooling capacity, and low energy consumption, they enhance operational efficiency.

Our ground support equipment for fighter aircraft is designed to meet the maintenance, refueling, and operational needs on the apron. Built to withstand demanding military standards, it delivers superior durability, reliability, and performance—maximizing mission readiness and operational uptime.

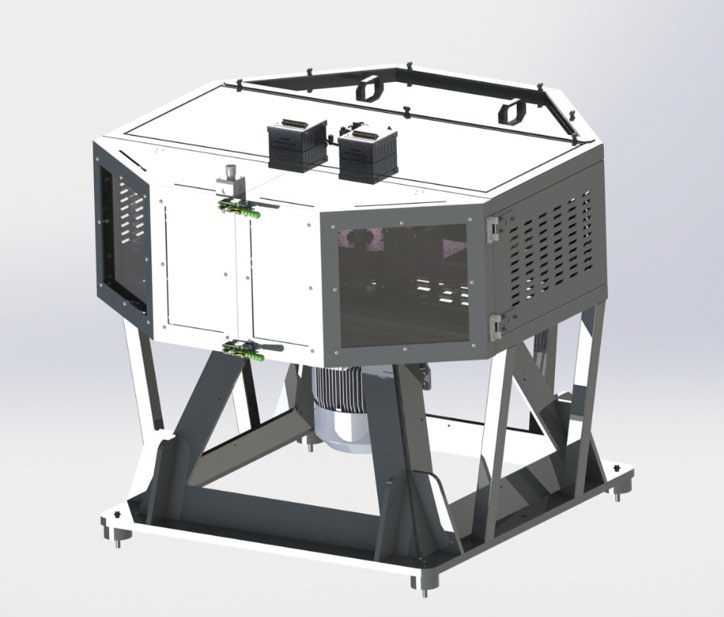

The Jumble/Jolt test equipment is designed to assess vibration resistance, impact durability, and loose part detection in assembled systems. It ensures reliable results in quality control and verification processes across various industrial applications

Designed to simulate high-speed operating conditions, the High-Speed Rotation Test Equipment is used to analyze the dynamic balance, structural integrity, and performance of rotating components. It plays a vital role in the defense, aerospace, and automotive industries, testing parts such as rotors, shafts, and turbines under mechanical and thermal stress at high RPMs. With its precise measurement capabilities and safe testing environment, it is essential for verifying product reliability under real-world operational conditions.

The Centrifuge Test Equipment is developed to evaluate the mechanical strength and functional reliability of components under high centrifugal forces. Widely used in the defense and aerospace industries, it enables performance testing of munitions, sensors, structural parts, and electronic components against G-forces. Equipped with advanced control systems and precise data acquisition capabilities, it ensures reliability and repeatability throughout the testing process.

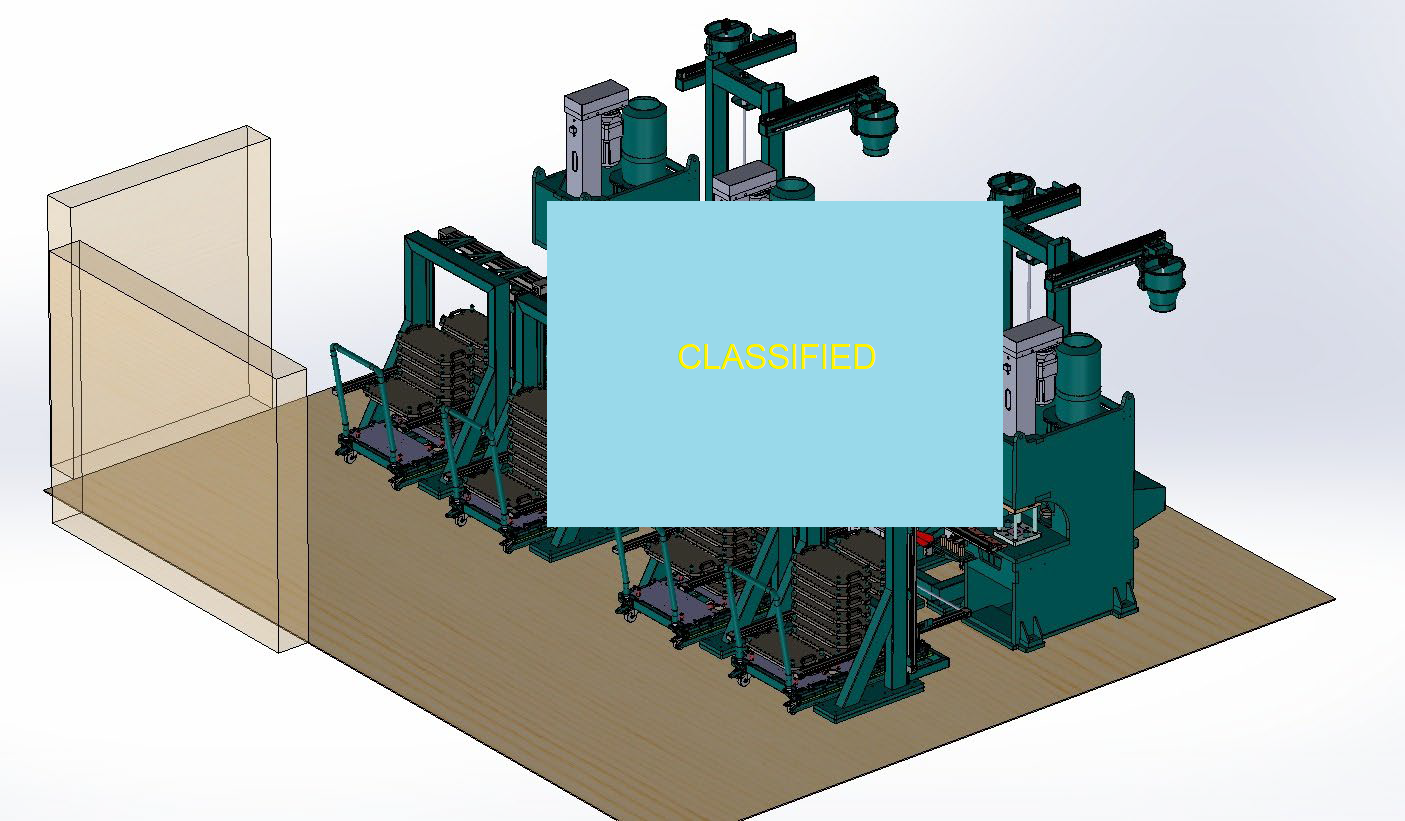

Our custom electromechanical R&D projects offer end-to-end engineering solutions, including original system design, prototyping, and testing tailored to customer requirements. In defense, aerospace, and industrial sectors, we develop innovative and reliable products in areas such as motion control systems, test infrastructures, and intelligent mechanical solutions. Project-specific flexibility, confidentiality, and technical depth are at the core of our approach.